Adjustable stroke, Double link motion

and High precision

The NXT high precision and high speed model is equipped with a double link motion mechanism. This mechanism allows a slide motion deceleration at around the bottom dead point for an optimal stability of the ram penetration and a drastic reduction of the vibrations inside the dies during the cutting and forming operations. The crankshaft is dynamically balanced. The frame material is casting iron FCD-50. The slide is guided by 2 plungers and 4 posts for a perfect action against eccentric load inside the dies. The change of the stroke length is fully automatic. As for all Yamada presses, the NXT model is equipped with an automatic oil temperature control (Heat & cool system) which permits to guaranty an optimal stability of the slide penetration from the first stamped parts at any constant speed or in acceleration. The Yamada easy handling press control with its color touch screen panel is very suitable for quick die changes with memorization of all the press and feeder parameters (for a total of 1000 dies). A press force monitoring is also included as standard equipment.

Fixed stroke, High speed link motion, High presicion

The MXM series link motion is the Yamada's original design and patented worldwide. This link motion is aimed to obtain higher speed. As a result of innovative design, the stampers can produce the products with the speed up to 2500 spm. The other features are similar to the NXT model: 2 plungers and 4 posts guide, automatic oil temperature control (Heat & cool system), dynamic balancer of the crankshaft for an optimal stability during the stamping operations.

Fixed stroke, Crank motion, Ultra High Speed

Commencing with the world highest speed press OMEGA-F1 which can reach speeds up to 4000 SPM!

Based on our long experience with ultra high speed stamping, Yamada has developped a new range of ulta high speed press 300 kN models named EPS-30 series which can reach speeds up to 3000 spm.

All those models are equipped with a special slide material alloy of ceramic and aluminium. This special alloy which is at the same time very hard and very light allows a significant reduction of the weight of the moving elements in order to maintain an optimal stability at around the BDC area.

The special floating bearings installed on the crankshaft permits to eliminate the metal contact and therefore reduce the friction resistance. Consequently the noise and vibrations are also minimized and the distortion caused by the excentric load is drastically limited.

Fixed stroke, Crank motion, High presicion

The ALPHA series are recognized as Yamada's best-selling crank motion press due to its simple mechanism (2 plungers and 4 posts slide guide), high speed, and high precision for many different types of stamping applications like connectors, electrical components, washers and motor lamination. Its very rigid frame made in casting iron guarantees an optimal rigidity and very low bed distortion. As all Yamada dobby presses the ALPHA series are equipped with an automatic oil temperature control (heat&cool system) which an optimal stability of the slide penetration from the first stamped parts at any constant speed or in acceleration.

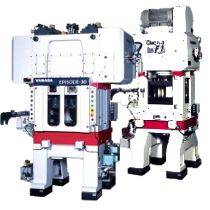

Lamination press with 3-Plunger slide guide

Looking at the aspects of energy efficiency, the motor core material is getting thinner and the required product accuracy tolerance is getting smaller. Seeking to improve the new motor effeciency requirements from our customers, Yamada has developped a new generation of 3 plunger and 4 post slide guiding lamination presses called EPISODE. The 3 plungers are dedicated to obtain a better rigidity in the middle of the slide and an optimal dynamic stability at the BDC area. The slide material is made in a special alloy of ceramic and aluminium directly resulted from our own research&development. This special alloy guarantees a harder and lighter slide aiming to obtain an optimal BDC precision.