Standard equipment for NXT, MXM and ALPHA/EPS Series:

| 1. | SRF Servo Roller Feeder | |

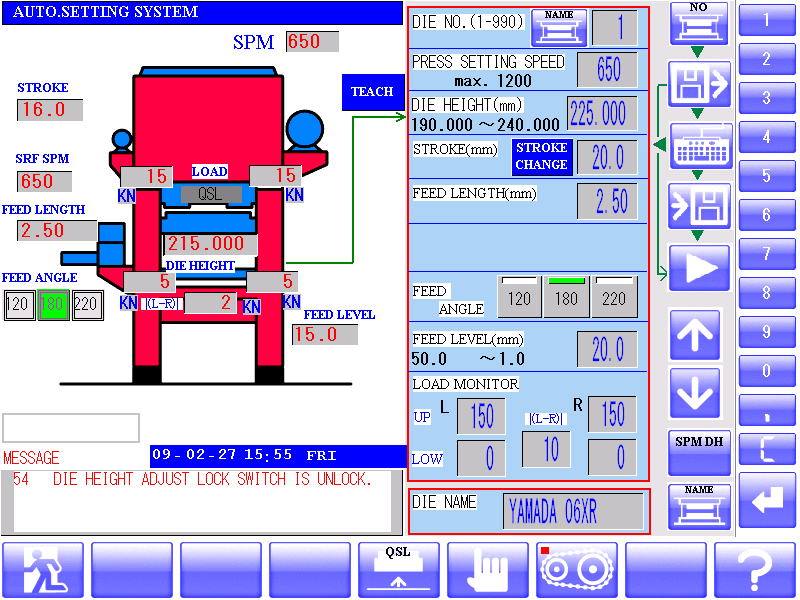

| 2. | Automatic setting system for 1000 die memory data (stroke length, SPM, die height, feed length, feed angle, pilot release angle, tool load data) Yamada 12″ compact LCD color touch screen panel | |

| 3. | Dynamic balancer of the crank shaft | |

| 4. | Crank shaft angle indicator (digital) | |

| 5. | Inverter motor / Slide reversing device | |

| 6. | Die-height indicator (1/1000 mm) / digital type | |

| 7. | Motorized slide adjustment for the die height | |

| 8. | Hydraulic slide lock device | |

| 9. | Quick lift of the slide with automatic positioning (memory - open - return) | |

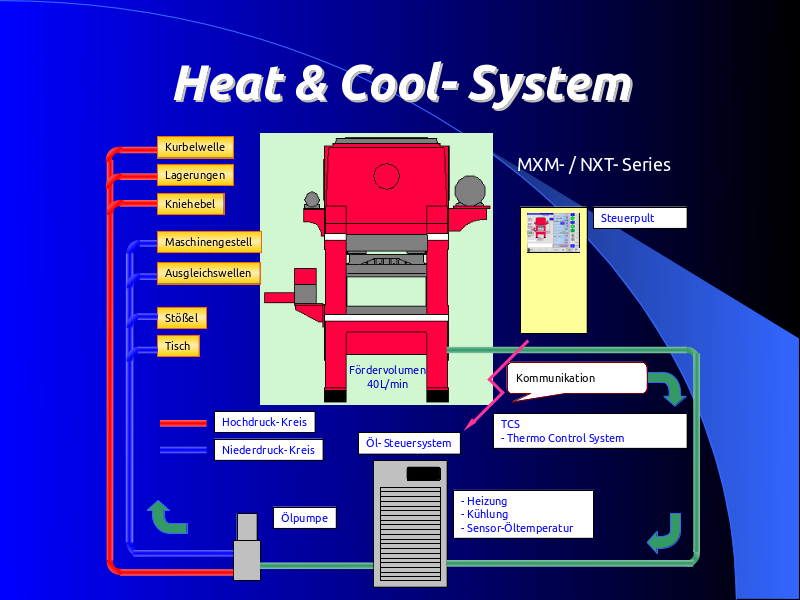

| 10. | Heat & cool system / automatic press oil temperature control | |

| 11. | Dynamic vibration protector (D.V.P) / vibration proof sub-legs | |

| 12. | Programmable digital cam / 10 free units / output 24VDC | |

| 13. | Input signals for ″immediate stop″ or ″TDC″ stop, output signals for ″continious″ stroke and for ″clutch engaged″ for peripheral equipments | |

| 14. | Transformer block supplying 220 and 380 VAC, protected by 30 mA leakage breaker | |

| 15. | Yamada press force monitoring with display in kN, 2 channel version - left & right sides / Piezo sensors installed on the press columns Indications: accumulated force and force of each channel, tool protection with maximum and minimum input as accumulated force | |

| 16. | Digital multi-meters (9 digit preset counter, 9 digit total counter, SPM meters, ampere meter, hour meter) | |

| 17. | Digital speed controller | |

| 18. | Oil and air pressure display and monitoring | |

| 19. | Pendant switches (inching & micro inching both hands, EM Stop, TDC Stop) | |

| 20. | Stop Connectors (2 x EM Stop, 2 x TDC Stop) | |

| 21. | Blow-off equipment controlled by cam / 4 cam outputs ready | |

| 22. | Air gun (for die area blow cleaning) | |

| 23. | Waste oil tank / for wasted spray oil evacuation / 1.6 liter capacity | |

| 24. | Telescopic strip guide (with SRF feeder) | |

| 25. | Strip end sensor (with SRF feeder) | |

| 26. | Front and back safety doors | |

| 27. | Die lamp (fluorescent type installed back side) | |

| 28. | Electrical cabinet cooler |